your best Business Partner

We manage the entire product manufacturing process — including technical proposals, design, production, integration, testing, validation, and certification — within our company. This approach requires ongoing investments in infrastructure, personnel, and technology.

It ensures a steady accumulation of know-how and affords us significant flexibility in managing both large volumes and small production runs.

DESIGN AND

DEVELOPMENT

PROJECT

MANAGEMENT

MECHANICAL

PRODUCTION

SYSTEM INTEGRATION

& TESTING

ENVIRONMENTAL

TESTING LABS

System Design

Mechanical Design

Electrical Design

HW / FW Design

FPGA Design

Thermal Simulation

Finite Element Method Analysis

FMECA Analysis

RAMS Analysis

Obsolescence Management

Product Validation

Risk Analysis

Project Management

Configuration Management

Risk Management

CNC Milling Machines

Punch Laser Station

Automatic Punching Stations

Automated Panel Bender

Bending Stations

Automated and Manual Welding Stations

Automated Foam Sealing and Gluing Center

SurTec Passivation Plant

Automatic Powder Coating Tunnel

Serigraphy and Digital Printing Laboratory

Large Builds 3D Printer

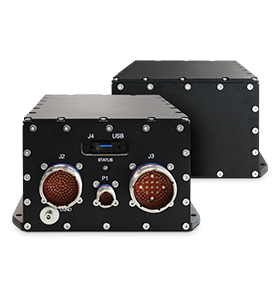

Electronic Boards Integration

Servers and Industrial PC Assembly

Electromechanical Assembly

Industrial, MIL and Custom Wiring Execution

Operative System Installation

Embedded Real Time Kernel Development

SW Application Development

Functional Testing | Burn-In

Electrical Safety Tests

IN-HOUSE EQUIPMENT

Climatic Rooms

Walk-in Climatic Room

Semi-Anechoic Shielded Chamber

Conducted Immunity Testing Area

Electro Dynamic Shaker with Head Expander

Dry Corrosion Chamber

IP dust test Chamber

IP Liquid Testing Area

COMPLIANCES & QUALIFICATIONS

EMI / EMC Compliance

Temperature Cycles

Humidity Cycles

Shocks e Vibrations

Acoustic Noise

IP Testing (CEI EN 60529)

Salt Fog Testing

UE Compatibility

Qualifications According to MIL-STD-461

Qualifications According to MIL-STD-810

Qualifications According to MIL-STD-167

Qualifications According RTCA/DO-160 (Avionic Standard)

Qualifications According to EN50155 e IS402 (Railway Standard)

Qualification According to IEC 60945 e Lloyd’s (Naval Standard)

ENVIRONMENTAL STRESS TEST (ESS)

Temperature Cycles

Humidity Cycles

Shock and Vibration Cycles